So I’ve been thinking about going into figurine making on a scale shown here but think it might be a waste to have a 3D print done just to make moulds that would only give detail in one direction.

So I’m pondering a different method where I make the moulds in Zbrush and have their positives made using a CNC Machine. I’m blindly assuming that CNC services are cheaper but if it worked, Making the actual moulds would be a lot easier then with a full 3D model. Just pour in some plaster or other such material and hopefully keep the positive for later.

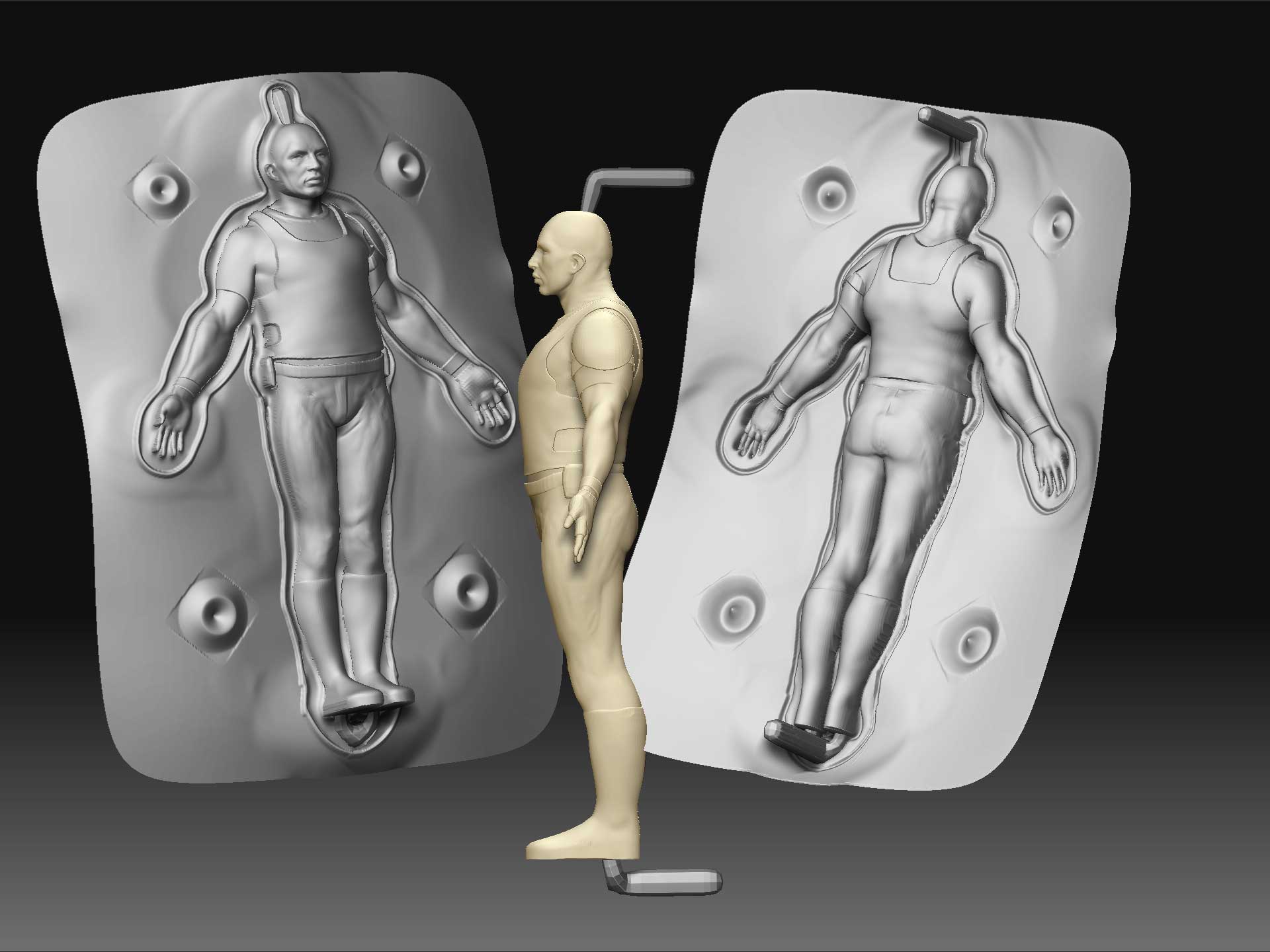

I’m still looking at the best and fastest way to make the models. So far i have a base plane that i sculpt to meet the model’s parting line, Some Zsphere tools for feeding lines and the model it self. Up the document res, copy the base plane and go at it with Zproject. after one side is done, I placed some shapes and a border for alignment and hopefuly containment. I make the other side with the first half visible instead of the base.

It’s not perfect and no matter how high res the mesh is, the edges of the mould are a bit jagged. I haven’t found any CNC machines around to test it but I’m hoping for some advice on the moulding side of things and weither i’m on the right track.

Attachments